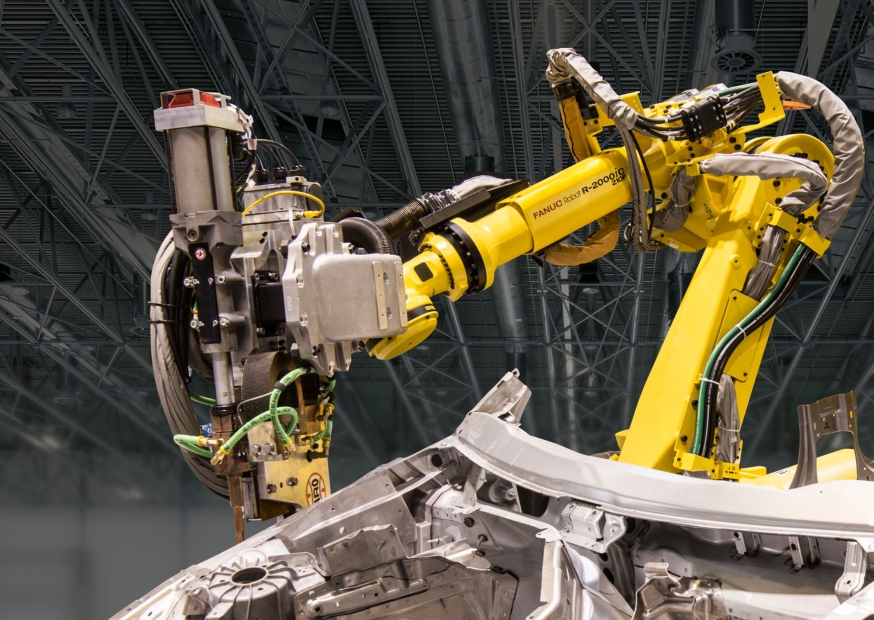

Robotic arms, at the center of modern production and manufacturing, are changing the norms in a way previously thought to be impossible to imagine. They combine precision, safety and efficiency. These marvels of the mechanical realm, commonly referred to as robot arms, have become indispensable in many industries around the world, driven by the urgent need to reduce operating expenses while ensuring high standards of quality. Integrating robotic arms into manufacturing lines allows manufacturers to not only cut costs, but also enhance work safety and efficiency. Learn how these cutting-edge machines have transformed the landscape of industrial production.

Image credit: automatedsolutions.com.au

The driving force behind the global surge in robotic arm usage is cost efficiency. Owners of factories are under constant stress to prevent the risk of injuries at work, eliminate production errors, and cut down on waste. A robotic arm tackles these challenges. In contrast to human workers, robotic arms perform repetitive tasks with pinpoint accuracy which eliminates costly errors and reducing raw material wastage. For instance, in high-volume industries such as automotive manufacturing, robot arms perform precise welding and part placement to ensure perfect assembly each time. This accuracy translates into substantial savings as less defective products mean less rework and less waste.

The security of robot arms is an essential element. Numerous manufacturing jobs like handling hazardous materials, or operating heavy machinery pose significant risks to workers. Robot arms allow companies to get their workers out of dangerous surroundings and decrease injuries in the workplace. Robotic arms, which are made up of joints that move could mimic the function of human arms without causing physical damage. The machines are fitted with robotic hands, or programmable end-effectors. They can perform tasks like grasping, spinning and welding in conditions that would make it dangerous for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms can adapt to numerous tasks, from automotive assembly to electronic production. The programability of these arms allows them to perform complicated tasks such as painting or applying fiberglass at a remarkable level of consistency. Robotic arms in warehousing have revolutionized palletizing by automating the load of goods onto pallets. The automation improves productivity as well as efficiency because robot arms operate all the time, never tiring.

One of the most intriguing advancements in this field is the development of collaborative robots or cobots, which interact with human employees. Unlike traditional industrial robots confined to isolated cells, the cobots that are equipped with robotic arms are designed to ensure safe and seamless interactions with humans. Cobots with robotic arms can be used to complete difficult or repetitive lifting tasks in a factory and allow human workers to focus on more complicated duties. The collaboration improves productivity and ensures a safe work area, since cobots are trained to stop or change their movements when a human is nearby.

The impact of robotic arms goes far beyond safety and efficacy to the very core of modern manufacturing. Their capability to do tasks such as welding, assembly, or handling of materials with precision has made them indispensable in high-risk industries. For instance, in automotive production, a robotic arm can move and rotate parts during assembly, ensuring the perfect alignment of parts without human intervention. Similar to electronic manufacturing, robot arms deal with delicate components carefully, minimizing damage and improving output quality.

As the world’s industries continue to develop robotic arms’ importance will continue to grow. Because they are able to cut costs, improve safety, and adapt for different tasks, robotic arms are essential to the future of manufacturing. Robot arms, that combine cutting-edge technology and human creativity They are not just tools as much as they are partners in progress. They are the engine behind innovation and transform the way in which the world is constructed.